How Flame Retardant Mesh Fabric Enhances Industrial Safety

Flame retardant mesh fabric is a textile with flame-resistant properties and a mesh-like structure, combining breathability, lightweight design, and fire protection. Typically made from fibers like polyester or nylon, it is widely used in environments requiring fire safety. This article explores the definition, characteristics, types, applications, advantages, disadvantages, and purchasing guide for flame retardant mesh fabric, helping industry buyers, product designers, and consumers understand this critical material.

Advantages and Characteristics of Flame Retardant Mesh Fabric

1.Flame Retardancy

Flame retardant mesh fabric achieves its fire-resistant properties through the use of halogen-free flame retardants (e.g., nitrogen-phosphorus-based agents). These form a protective film on the fiber surface, slowing combustion and reducing flame spread. Compared to traditional halogen-based retardants, halogen-free options offer better stability at high temperatures, maintaining effectiveness above 500°C, while halogen-based agents typically fail around 300°C and release toxic gases.

2.Breathability

The mesh structure’s size directly impacts breathability. Many high-performance flame retardant fabrics use composite materials of elastic and polyester fibers, creating a structure that is both breathable and thermally insulating. This ensures good air circulation, preventing excessive heat buildup in high-temperature environments.

3.Strength and Durability

Flame retardant mesh fabric offers excellent tensile strength (50-70N) and tear resistance (above 50N), enabling it to withstand significant stretching and external forces in harsh conditions. Anti-static treatments prevent static buildup from friction, reducing fiber damage. This fabric is widely used in outdoor backpacks, military vests, protective clothing, and other gear, enduring high-intensity stretching and friction while maintaining performance and durability in extreme environments.

4.Lightweight

These lightweight fibers provide flame retardancy while maintaining low density, typically between 60-200 g/m², with some exceeding 300 gsm.

The mesh structure reduces weight while preserving breathability and comfort. Compared to traditional fire-resistant fabrics, flame retardant mesh fabric is lighter and thinner, ensuring comfort during prolonged high-intensity work.

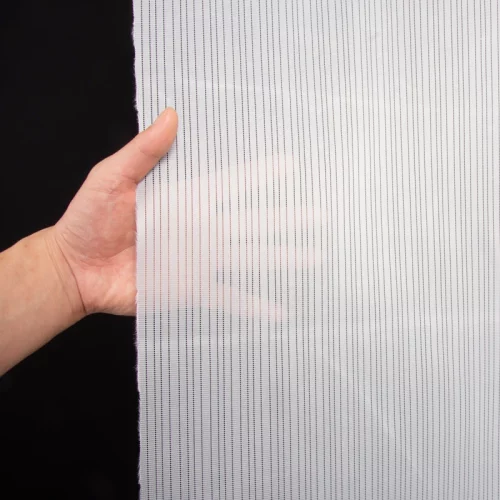

5.Transparency or Semi-Transparency

The transparent or semi-transparent nature of flame retardant mesh fabric stems from its mesh structure, with light transmission adjusted by controlling mesh size and density. Larger mesh openings provide higher transparency, while smaller ones enhance privacy while maintaining semi-transparency. For example, in mosquito nets and protective covers, larger mesh openings block insects while ensuring breathability and light transmission. In safety barriers and partitions, the fabric offers privacy and ventilation.

Disadvantages of Flame Retardant Mesh Fabric

1.Privacy Concerns

While transparency or semi-transparency is an advantage, it may compromise privacy in applications requiring complete opacity or confidentiality.

2.Susceptibility to Snagging or Damage

Due to its mesh structure, the fabric is prone to snagging or damage. Care must be taken to avoid contact with sharp objects or excessive stretching.

3.Need for Additional Liners in Some Applications

In applications requiring extra strength or complete flame resistance, flame retardant mesh fabric may need to be paired with liners to enhance overall performance.

Types and Applications of Flame Retardant Mesh Fabric

Polyester Mesh

The most common type, polyester mesh offers excellent flame retardancy and abrasion resistance, used in clothing, home textiles, and industrial applications such as sportswear, backpack linings, shoe materials, filter fabrics, outdoor chair netting, window screens, and medical bandages.

Nylon Mesh

More durable than polyester mesh, nylon is suited for high-strength and durability applications like firefighting suits and protective clothing, as well as luggage, military vests, helmet padding, outdoor gear, pet products, and swimwear linings.

Polypropylene Mesh

With strong chemical resistance, polypropylene mesh is ideal for environments requiring resistance to chemical corrosion, such as medical filtration (e.g., masks, protective covers), food-grade filters, chemical filtration nets, and agricultural cover nets.

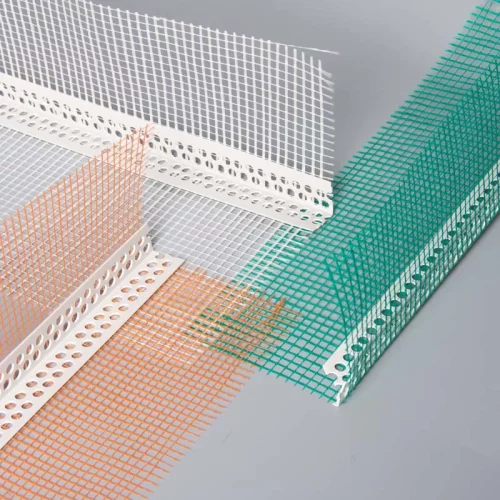

Fiberglass Mesh

Known for excellent high-temperature resistance, fiberglass mesh is used in high-heat environments like metallurgy, as well as exterior wall insulation systems, tile/marble backing, wall crack reinforcement, fiberglass-reinforced materials, and roof waterproofing.

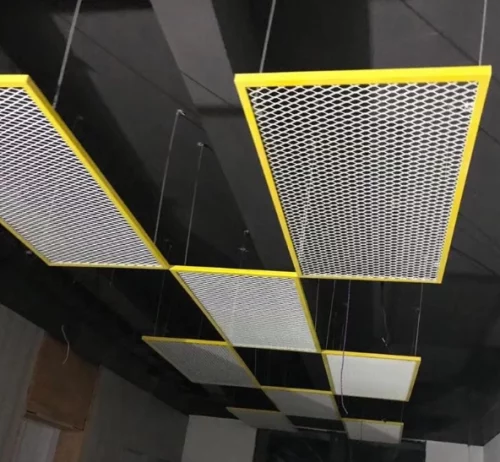

Metal Mesh

With superior heat and abrasion resistance, metal mesh is used in extreme conditions for industrial filtration, screening equipment, architectural decoration, vent covers, rodent/bird protection, and electromagnetic shielding.

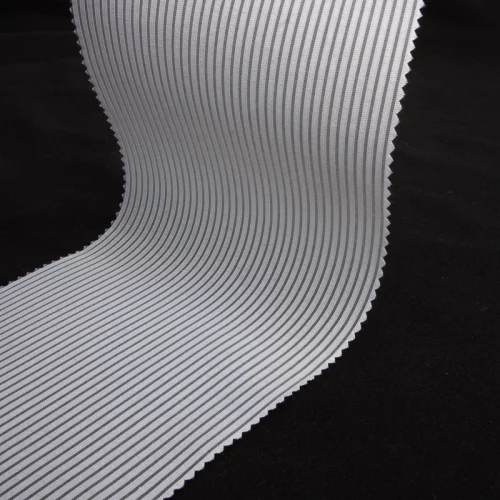

Spandex Mesh

Elastic spandex mesh is used in clothing and products requiring stretch, such as sportswear, stage costumes, fitness apparel, shapewear, underwear, leggings, and medical support bands in high-temperature environments.

Environmental Impact

BEGOODTEX mesh fabric uses halogen-free flame retardants to reduce environmental pollution and complies with international environmental standards.

Made from recyclable and biodegradable fibers like recycled polyester and natural fibers, it ensures eco-friendliness. The fabric withstands over 30 washes while maintaining B2 flame-retardant standards. Using high-strength polyester-nylon composite fibers, it offers enhanced tensile strength (up to 20% stretch) and tear resistance (up to 50N), ensuring long-term durability in harsh conditions.

BEGOODTEX adheres to international standards like OEKO-TEX Standard 100 and Global Recycled Standard (GRS), ensuring products are safe for humans and environmentally compliant.

Purchasing Guide for Flame Retardant Mesh Fabric

1.Determine the Application

Choose the appropriate flame retardant mesh fabric based on the use case. For high-temperature operations (e.g., metallurgy, chemical industries), select fabrics with high heat resistance and flame-spread prevention, such as polyester-nylon blends for superior heat resistance and strength. For industrial protective clothing, prioritize comfort and breathability with highly breathable polyester mesh.

2.Consider Materials

Material choice determines performance. Polyester is a common flame-retardant material with high abrasion resistance, suitable for most industrial applications. Nylon offers better heat resistance and tensile strength, ideal for firefighting and high-temperature environments. For extreme heat resistance, fiberglass withstands temperatures up to 1000°C, making it perfect for metallurgy and firefighting.

3.Mesh Size Selection

For high-protection and fire-resistant applications, such as construction or chemical manufacturing, smaller mesh sizes provide greater strength and flame resistance by reducing flame-spread opportunities, ensuring optimal safety.

4.Focus on Special Features

Select fabrics with additional features based on needs. Anti-static properties are crucial for the electronics industry to prevent static buildup and fire risks, typically achieved through conductive fibers or coatings.

5.Consider Maintenance

Washability and durability are critical for long-term use. Ensure the fabric withstands at least 30 washes without losing flame-retardant properties. Fabrics with anti-stain treatments resist oil, chemicals, or dust, simplifying cleaning and maintenance. For example, fabrics with oil-resistant and easy-clean coatings reduce maintenance efforts.

6.Budget Considerations

Choose fabrics based on functional needs and usage frequency. For tight budgets, basic flame-retardant polyester mesh meets general industrial needs. For additional features like anti-static or UV resistance, nylon-polyester composites offer better performance at a slightly higher cost. Plan budgets to balance functionality and cost.

Flame retardant mesh fabric, with its flame resistance, breathability, lightweight nature, and durability, is increasingly used in industrial safety, construction, agriculture, medical, and household applications. Through continuous innovation and eco-friendly materials, BEGOODTEX’s flame retardant mesh fabric meets modern industrial safety needs while providing sustainable solutions. As flame-retardant technology advances, this fabric will play an even greater role in future industrial safety.

FAQ

Q: How does flame retardant mesh fabric improve safety in industrial settings?

A: Flame retardant mesh fabric enhances safety by providing both fire resistance and breathability, crucial for workers in environments with high fire risks. Its lightweight design allows for comfort while still offering robust protection against flames.

Q: What industries benefit the most from using flame retardant mesh fabric?

A: Flame retardant mesh fabric is highly beneficial in industries like construction, firefighting, agriculture, military, and medical sectors, where workers or equipment are exposed to high heat, fire, or hazardous chemicals.

Q: Can flame retardant mesh fabric be used for personal protective clothing?

A: Yes, flame retardant mesh fabric is commonly used in personal protective clothing such as firefighter suits, military vests, and outdoor gear. Its combination of fire resistance, durability, and comfort makes it ideal for such applications.