What Is Flame retardant Waterproof Fabric?

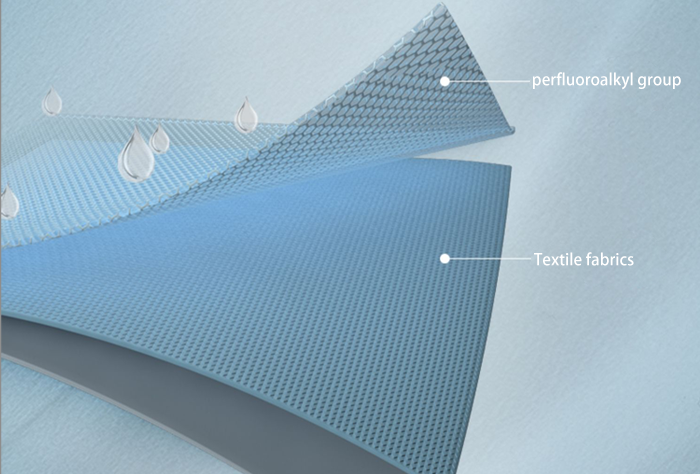

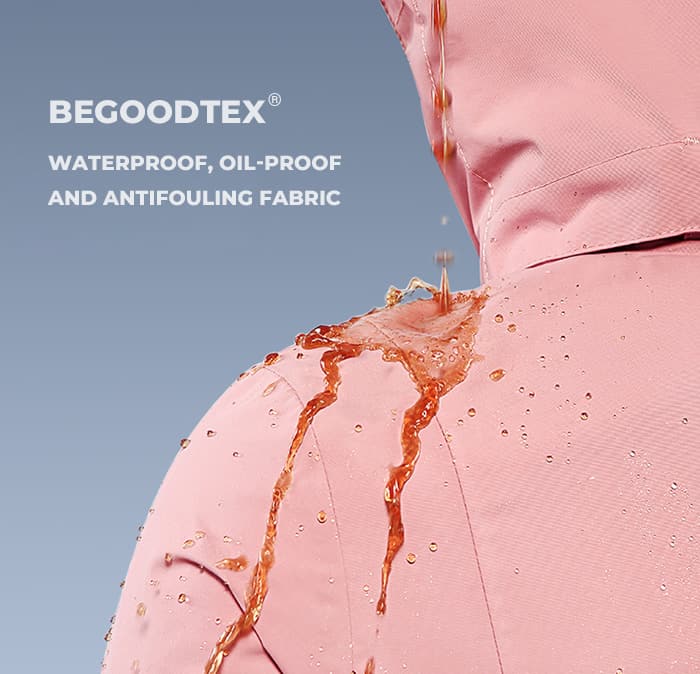

The term “three-proof” fabric refers to fabric that has been treated with technology to form a stable air interface protective film on its surface. This film helps prevent water, oil, and stains from penetrating the fabric. The fabric treated with such a process is called a “three-proof” fabric.

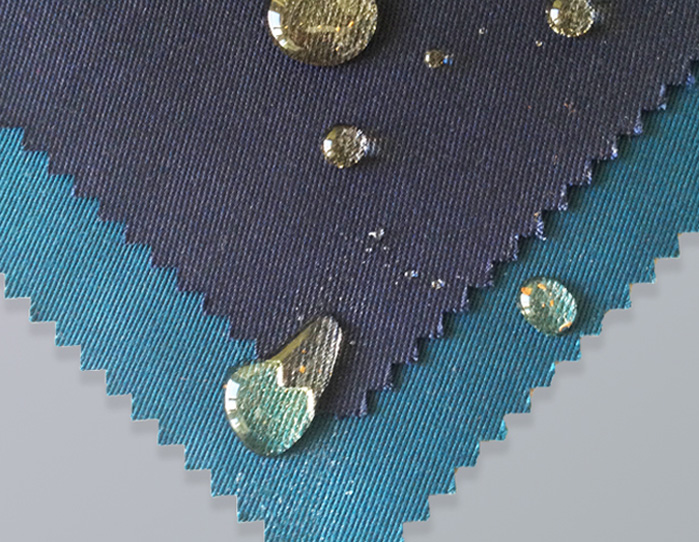

The true waterproof and oil-proof fabric refers to the fabric that can resist oil without soaking it and can resist water without seeping.

It is suitable for making protective workwear that frequently comes into contact with oil and water, and is widely used in industries such as petroleum, chemical, gas stations, mining, chef uniforms, repair, and others.

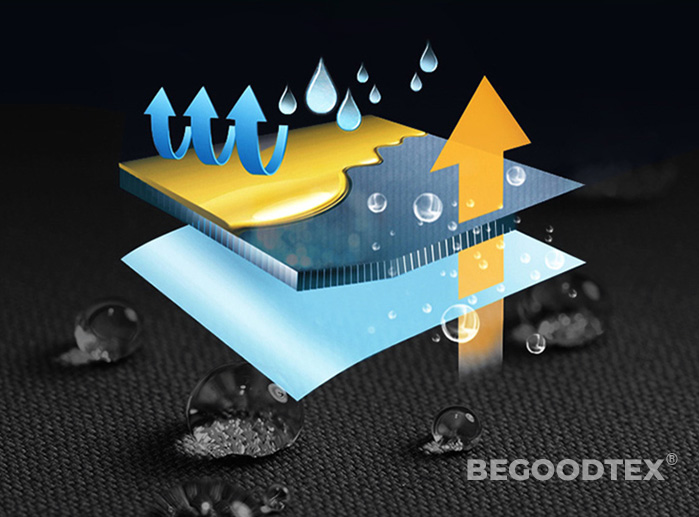

Waterproof: The fabric is coated with a water-resistant film that prevents water penetration without closing the fabric’s pores, making it both water-resistant and breathable.

Oil-proof: When the fabric does not absorb oil, it exhibits oil resistance.

Anti-stain treatment involves reducing the speed and degree of soiling, making it easier to clean. This includes finishes that are both easy to clean and resistant to dirt.

Easy-to-clean fabric refers to fabric that is simple to wash or wipe clean after being stained by pollutants. The fabric treated with an easy-to-clean agent has dual functions: anti-stain and easy-to-clean. In other words, it is resistant to oil stains during use. Once stained, it can be easily washed under normal conditions.

If the fabric has oil and water resistance as well as anti-stain properties simultaneously, it can be referred to as a “three-proof” fabric.